Taking Print to a Whole New Dimension

“Imagine a world where the solar panel on your mobile phone is so good it never runs out of charge. Now imagine that the same mobile device monitors your health and diagnoses and prescribes your medication, which you download to your device. Then, you connect the device to your 3D printer at home and print that medication out, tailored specifically to you.” Mark Stevenson, Futurist.

Science fiction, right? After all, whoever heard of printing pills? Wrong, not only is it in development, it’s just around the corner. In fact, it might already be out of date. Website, 3D Printing Industry reported earlier this month that Solido3D is crowd sourcing funding to create OLO, a device that actually converts your smart phone into a 3D printer. Click here to see how it works, it’s pretty cool.

And if you think that is incredible then this will blow your mind. Printing human organs; it is on the cards. Doctors are already using 3D printing to create knew replacement joints and research and experimentation in to 3D bioprinting – the printing of human cells to form complex, living tissues – is ongoing and has the potential to completely transform healthcare.

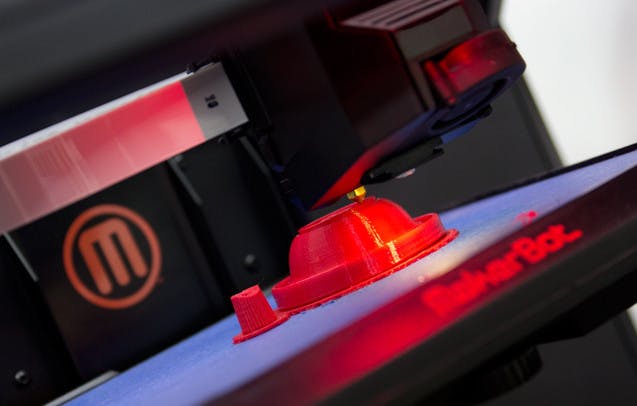

3D printing is the future, not just of printing, but in so many areas of business and health. It is the future of manufacturing, the future of design and essentially, the future of innovation. It is a future we at Springfield Solutions have taken our first steps into by investing in a Makerbot Replicator 3D printer. OK, we are not thinking of printing human kidneys with it just yet, more plastic components for our prototype packaging service mock>it, but we are nevertheless extremely excited by the potential it holds.

And we are extremely excited by finding out how far we can take it. We have done that with other forms of printing, stretching analogue as far as it could go before changing over to an entirely digital platform. Now we are adding 3D printing, and already our investment is bearing fruit.

So where will 3D printing take the world? Twitter co-founder, Biz Stone, predicts that Nike will be a pure software company in 10 years. They will design the products, but leaving the manufacturing to you and me by the click of a mouse. It is set to be the biggest revolution in manufacturing since Henry Ford created the assembly line.

But even before that, radical changes will take place as a result of the new technology.

There will be a huge increase in final products being printed, rather than prototypes. Currently our printer is used for prototyping but I can see a time, in the not too distant future, when we will be printing packaging components directly for our clients. About 20 per cent of final products are presently created by 3D printers. Industry forecasts predict this will increase to 50 per cent by 2020.

It follows therefore that additive manufacturing – the process of creating products via layering – is set to redefine how the world makes goods. It is not a new concept but it differs from subtractive manufacturing (that of cutting, drilling, bashing, etc) by requiring less raw material and, as it results from a software programme, doesn’t require retooling. It is set to reshape global manufacturing at a fast rate in a process that has already begun.

But if the manufacturing of large, complicated goods is still carried out by corporates, producing smaller consumables will become a more democratic affair. If Biz Stone is right about Nike, then it will be due to 3D printing. Suddenly their customers become their manufacturers. Instead of ordering a pair of trainers from the internet or, god forbid, going into a shop, they will download a file and print it. So it will be with mugs or coffee tables or window blinds or gloves.

There are challenges, of course. Currently most 3D printers work with one type of material – plastic, metal, ceramic, wood or biological substances, so to really fulfil their potential, they need to become capable of printing with several materials within a single build cycle. But this will happen, and this means printing complicated, multi-material items, drugs, body parts and organs, and much, much more will be capable, and a lot of it in our lifetimes. When it does, the potential of 3D printing becomes limited only by human imagination. To find out more about our 3D printing service please take a look at the following page:- http://www.springfieldsolutions.co.uk/brand-management/printing